Custom PCB

During the COVID crisis, we needed to figure out a new final project for Intro to Mechanical Engineering as they could no longer meet in groups. The professor proposed creating a custom Arduino shield to control motors and route power for a Climbing Robot. He designed the traces and I cut the boards on an Axiom CNC. We dialed it in after only a couple iterations and were able to produce 32 working shields for the class project. All in around six weeks from idea to distribution.

The biggest challenge for me was producing a viable toolpath from the provided Eagle file. I used Illustrator to make necessary modifications, such as increasing the width of the traces and making separate layers for the 4 drill sizes, then I finished the G-code in VCarve. Endmills at this size are quite fragile, and I went through my fair share. Once again, quality tooling produces quality results.

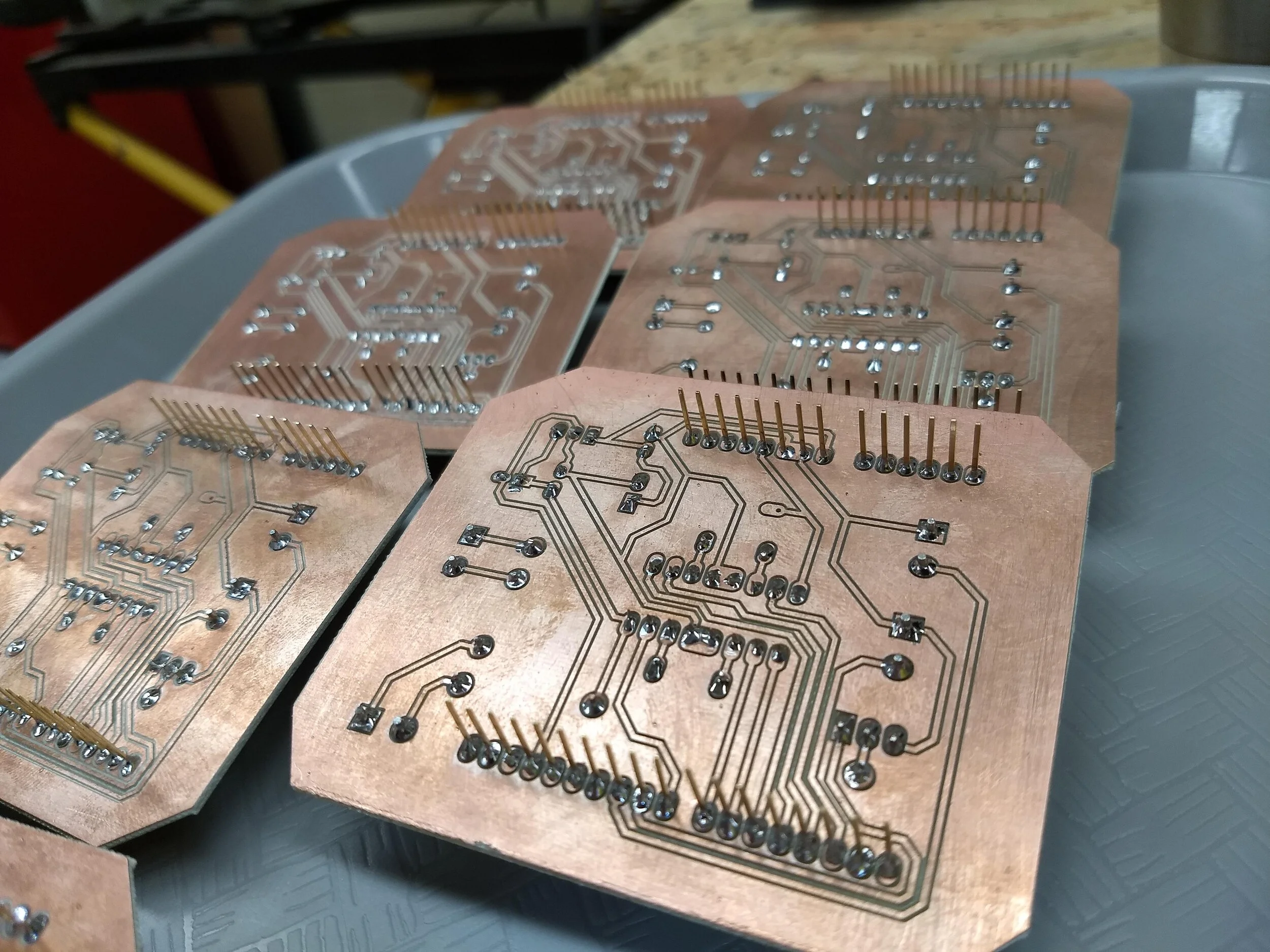

V1 ready for testing

Final design approved and in production

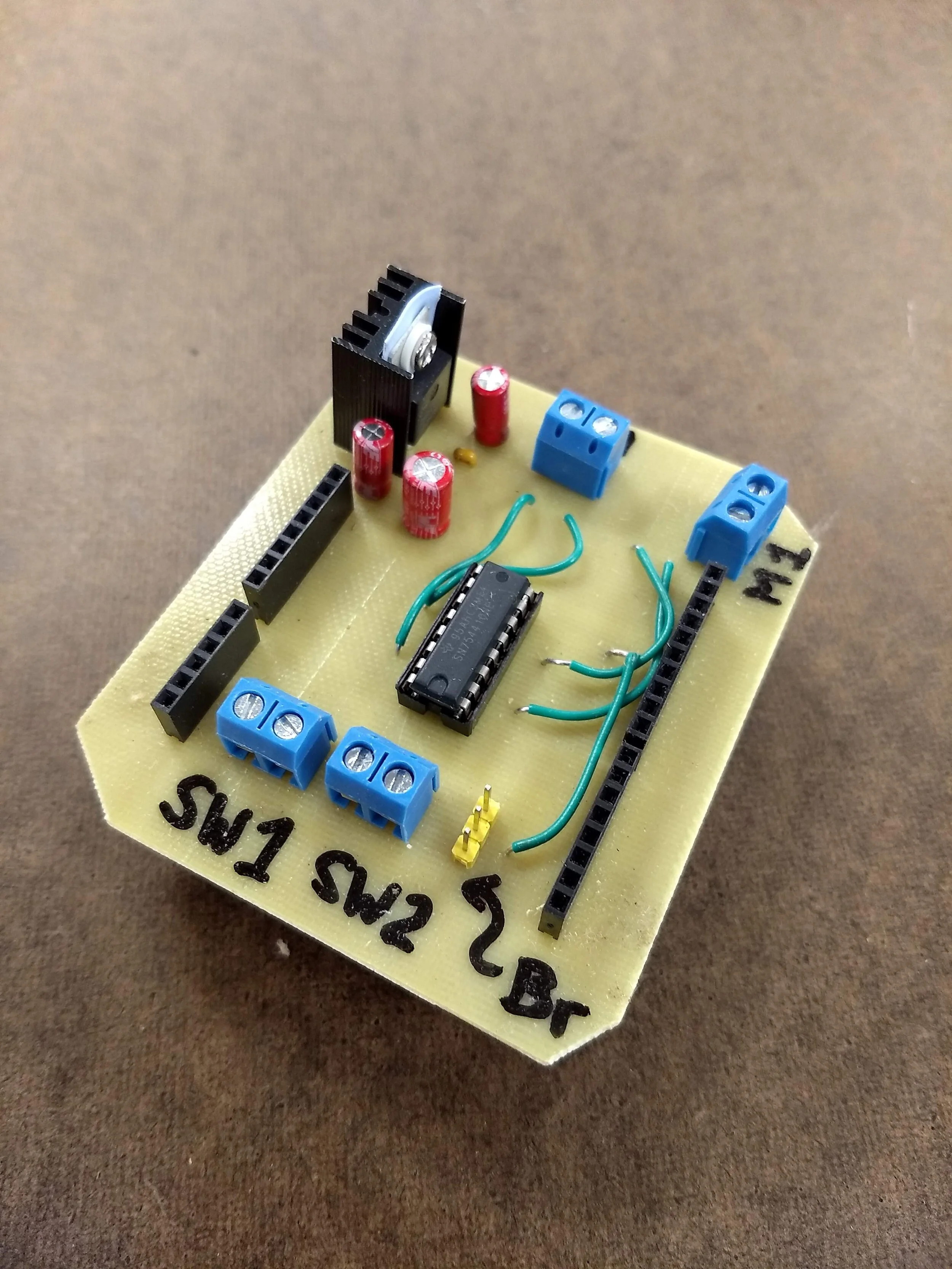

Assembled and working

Nice fit!